- GST No. 07BENPG1285H1ZE

| Business Type | Manufacturer, Exporter, Supplier |

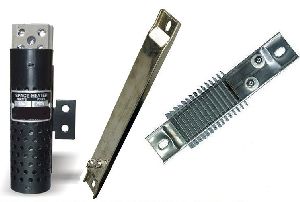

| Type | Industrial Heaters |

| Condition | New |

| Application | Water Heating |

| Click to view more | |

Product Details

Power Source

Electric

Specialities

Vibration And Shock Resistance, Rugged Construction

Maximum Weight

Aluminium 400kg / Cupronikel 300kg

Max Watt Density

20 w/cm² on the heating element

Brand

Fragma

The cast-in heating plates and heating bands consist of one or several electrical resistances embedded in a block of aluminum, brass, bronze or cupronickel alloy providing excellent thermal conductivity.

- Cast-in heating elements are ideal for applications requiring homogeneous indirect heat.

- Cast-in heaters are often used in plastics industry, packaging industry, food industry and many others.

Usual applications : heating plates for presses, extruder dies and sheaths, heating plates for homogeneous heating (rubber, aerated concrete curing), sealing on packaging lines, mills.

Product overview :

- Indirect heating

- Block of aluminum, brass, bronze or cupronickel alloy

- Process temperature up to +400°C (aluminium), +650 °C (cupronickel). Maximum +750°C

- Can be equipped with cooling circuits to optimize the industrial process

Advantages

- Gravity moulding ensures an excellent material homogeneity and thus a perfect heat transfer.

- Constant surface temperature is achieved through appropriate forming.

- As this is indirect heating, the heating resistance is protected. The solid or fluid to be heated is not in contact with the resistance.

- High protection against corrosion

- The end-to-end control of the design and production chain allows us to deliver a product which suits your process perfectly

- Resistance in severe industrial surroundings (impacts, vibration)

Looking for "Casting Heaters" ?

Piece